Standard Lumber Vs Floor Truss

With i joists this design is not possible.

Standard lumber vs floor truss. A typical wood frame floor covered with carpet or vinyl flooring has a dead load of about 8 pounds per square foot. However the installation of these requires more experience and training than sawn lumber. Wood trusses provide a very efficient use of materials and are excellent over long spans. Floor joist span use this table to determine the maximum lengths of floor joists based on species of lumber joist spacing and joist size.

So once again a 26 foot truss x 5 00 a foot 130 00 remember this is only quick estimating used only to get a ballpark figure. Floor trusses can be keyed and this will allow a longer overall span. Roof rafter span use this table to determine the maximum lengths of roof rafters based on species and grade of lumber spacing dimensions load and slope. These trusses are around 4 50 to 5 50 a foot.

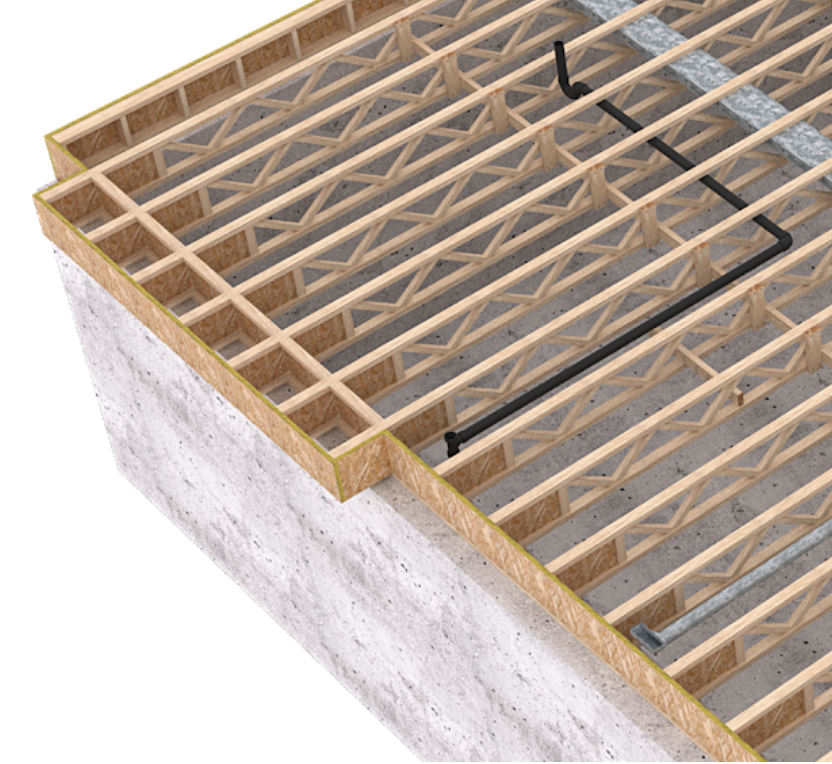

Energy trusses have raised heels so they can reach r values of 30 or higher. Plated floor trusses are very heavy present a handling danger because of sharp plate edges and plates often interfere with the installation of mechanicals. The dead load on a floor is determined by the materials used in the floor s construction. Squeaky or bouncy floors that result in callbacks fire code compliance challenges and difficulties installing mechanical systems more than one of these issues often arise when wood i joists are specified for floor framing.

If there s wall board covered ceiling suspended from the underside of that floor the dead load increases to about 10 pounds per square foot. That is 25 less lumber which means more money in your pocket as the builder and more money in the pocket of the homeowner. Most standard residential trusses can achieve r values r value referring to a rating that represents the insulation s capacity to resist heat transference from heated to non heated areas and vice versa of 11 or 13 near the sidewall. These trusses cost more than a common truss since there are more parts to cut and more lumber in the truss.

On shorter spans this will all but eliminate the splices needed and keep the truss at or below standard board lengths. Most floor truss tables only allow a 40 span to be built. Like the i joists they have a low moisture content after production so they shrink very little and result in few loose fasteners and subsequent floor squeaking. Steel is also a non renewable resource manufactured with great energy consumption.

Let s talk about cost on a standard gable truss. This is because floor trusses have a wider nailing surface that makes it easier to fasten everything together.