Stacking Fault Metal Ceramics Formation

The width of stacking fault is a consequence of the balance between the repulsive.

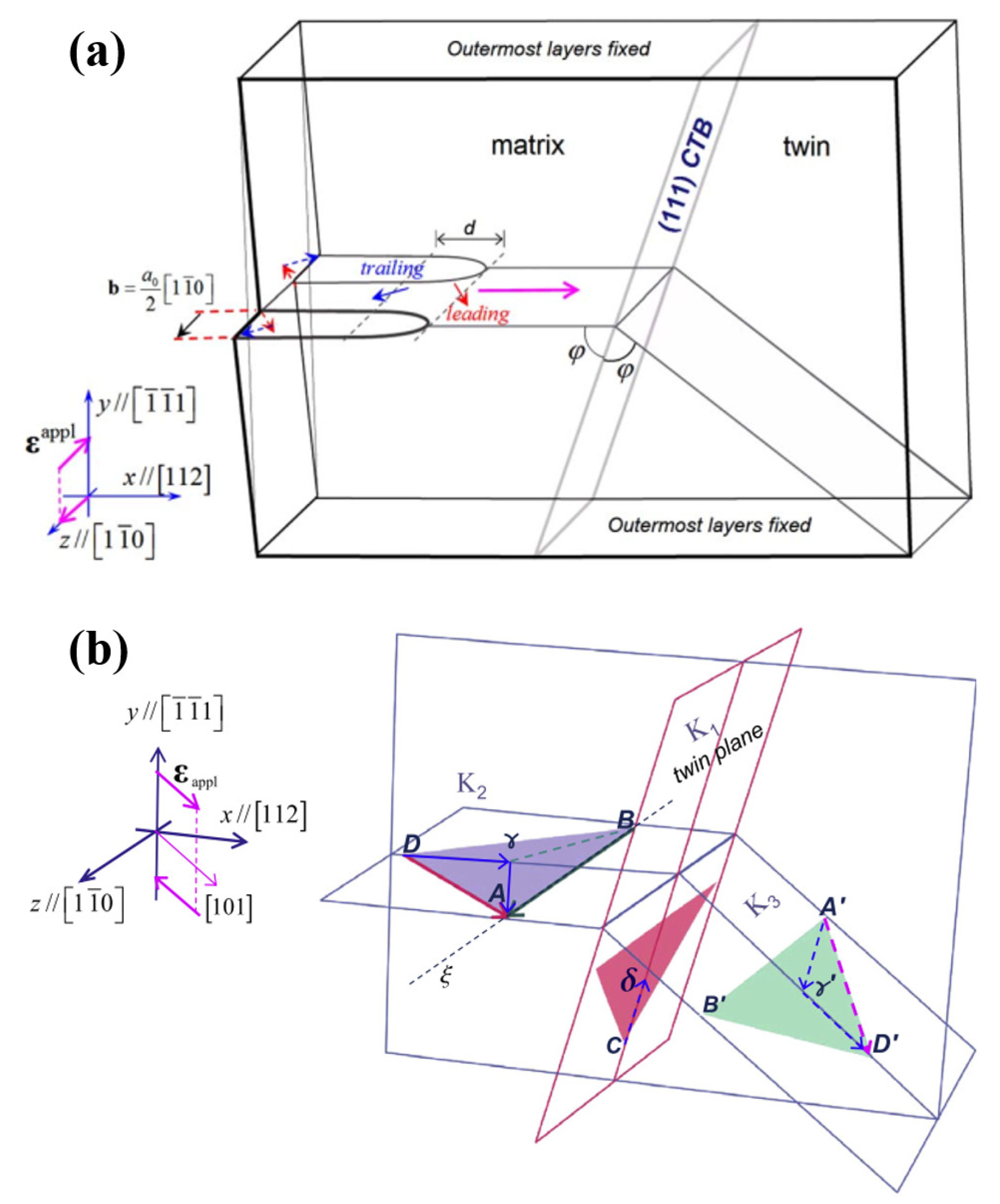

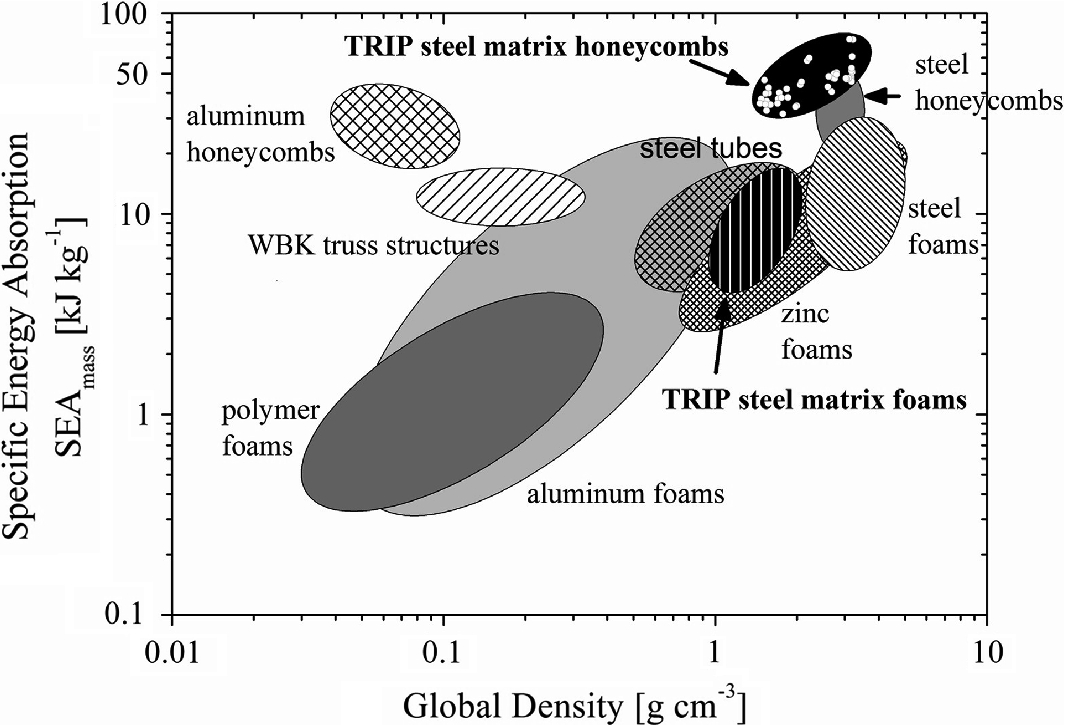

Stacking fault metal ceramics formation. The current finding not only unravels a new formation mechanism of stacking faults within wc grains but also provides a new route to design superhard cemented carbides with interlaced stacking faults by simply doping solute atoms and controlling the sintering process other than the traditional deformation method. The stacking fault energy sfe is a materials property on a very small scale. For 112 111 slip a stable stacking fault at a 0 3 112 displacement was formed in tin. For 110 111 slip a splitting of saddle point in tin was observed.

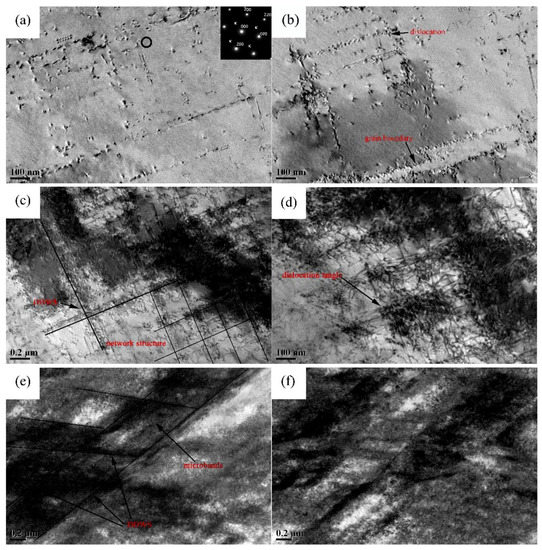

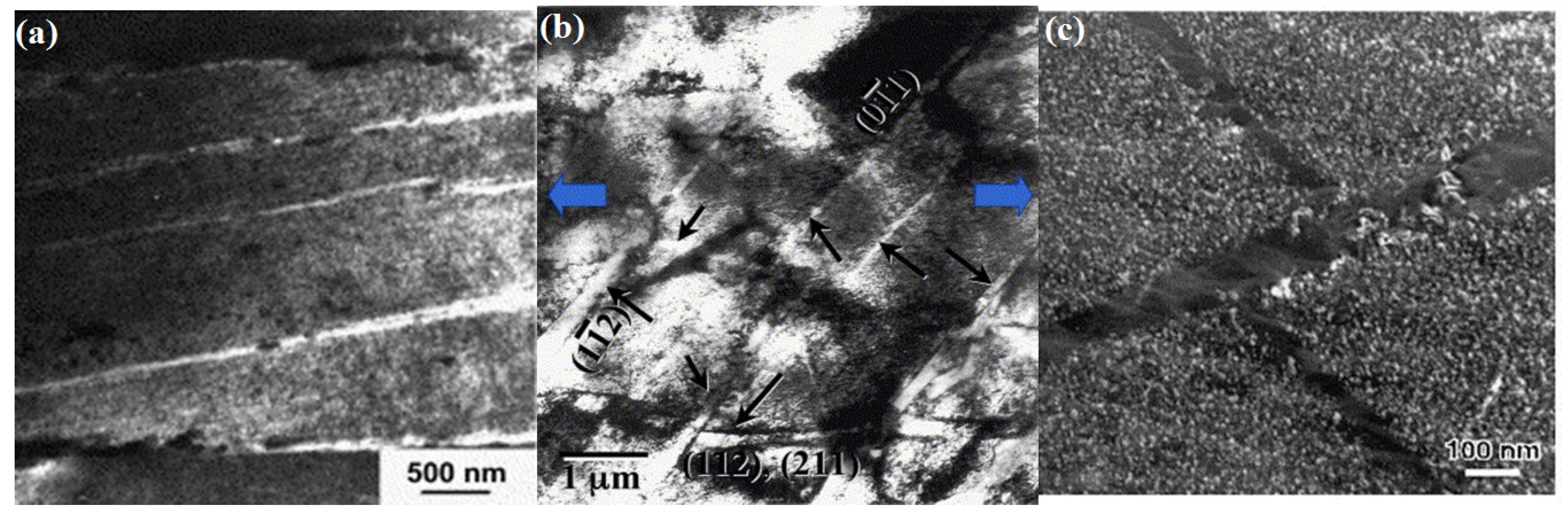

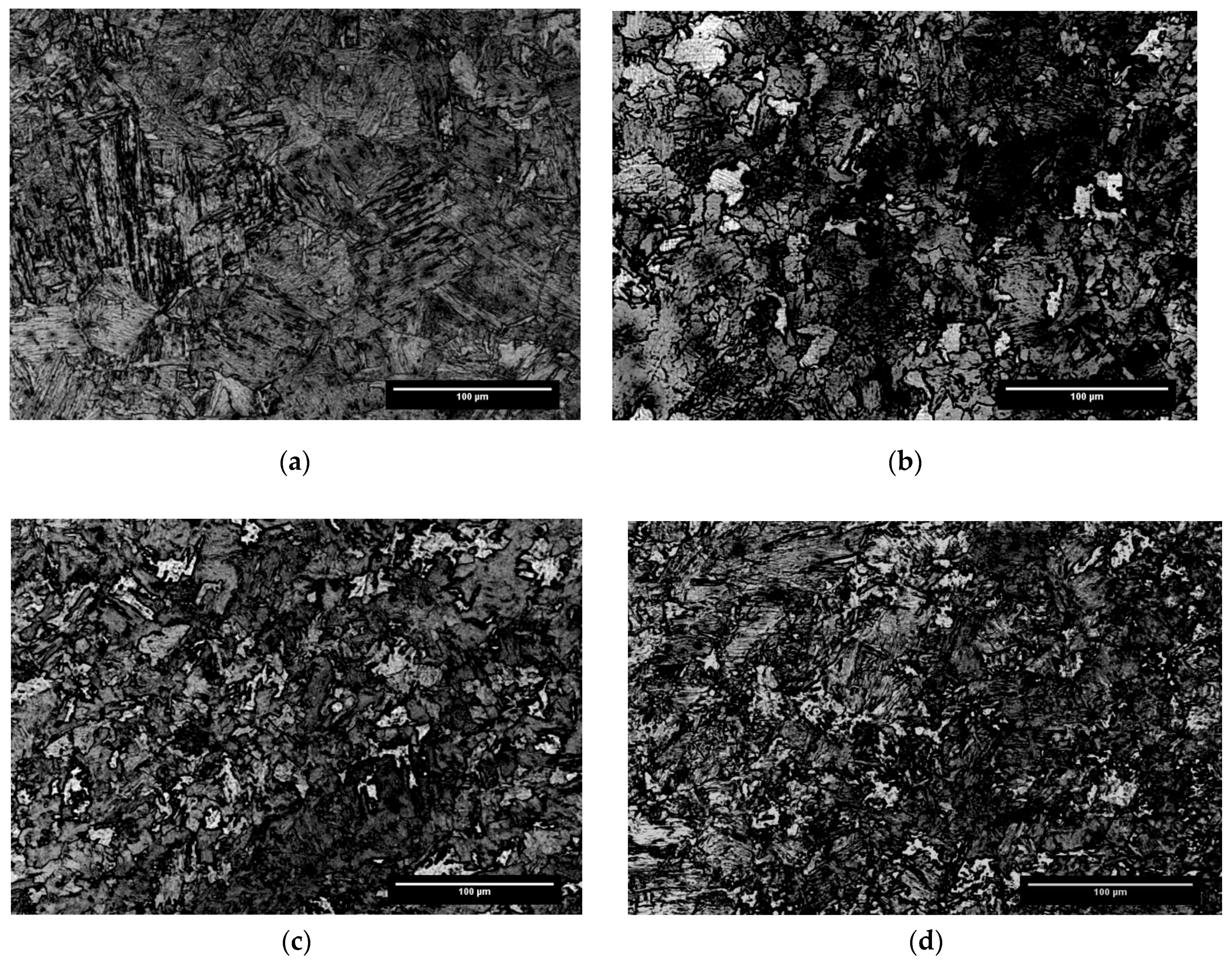

For high sfe metals dislocations are the predominant carriers to mediate the plastic deformation although twins are occasion ally activated at extreme conditions such as at crack tips during. A stacking fault is an interruption of the normal stacking sequence of atomic planes in a close packed crystal structure these interruptions carry a certain stacking fault energy. Formation twinning and partial dislocation enclosed stacking fault sf ribbons within grains 10 deformation twinning was experimentally verified in nc al 7 8 14 surprisingly sfs ob served in cryogenically ball milled ncal ref. 7 were found to be much wider than both the experimental value in coarse.

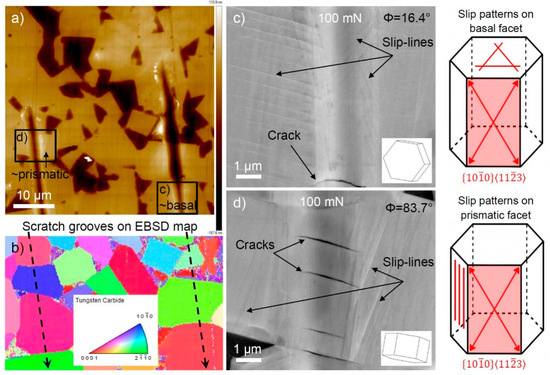

The β sic formed by the solid gas carbon sio gas reaction showed a. Factors affecting stacking fault formation during the synthetic fabrication of β sic were investigated in the present study. Stacking fault energy and microstructure e ects on torsion texture evolution by darcy a. Perfect basal dislocations with b b 1 3 1 2 1 0 have dissociated into pairs of prism plane half partials.

Stacking faults are two dimensional planar defects that can occur in crystalline materials. Stacking fault energy sfe or a low ratio of the unstable twin fault energy c utf to the unstable stacking fault energy c usf 6. Formation of stacking faults in fcc crystal. It is noted as γ sfe in units of energy per area.

They can be formed during crystal growth during plastic deformation as partial dislocations move as a result of dissociation of a perfect dislocation or by condensation of point defects during high rate plastic deformation. 13 41 formation of bsfs in gan can be considered as a wurtzite sphalerite transition within a. A high density of basal stacking faults was typically observed in iii nitride epitaxial layers near the interface with the substrate 10 12 15 there are three types i 1 i 2 and e of basal stacking faults observed in gan with one b two c and three d cubic bilayers respectively fig. Stacking faults in hot pressed hexagonal batio 3 the 6h polytype ceramic have been analyzed adopting the 2πg r f 0 or 2nπ invisibility criteria and dislocations were examined by the g b 0 effective invisibility criteria both using transmission electron microscopy.