Spruing Multiple Pressed Dental Ceramic

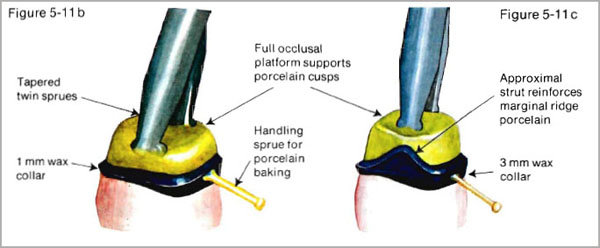

Place sprues on the thickest area of the pattern.

Spruing multiple pressed dental ceramic. Over the last decade it has been observed that there is an increasing interest in the ceramic materials in dentistry. The sprue former should be straight to reduce chances of creating turbulence in molten metal entering the mold. Press ceramic for zirconia framework restorations czr press technology consists of the marriage of two time proven technologies. Hence pressed ceramic restorations are far more durable and resistant to fracture.

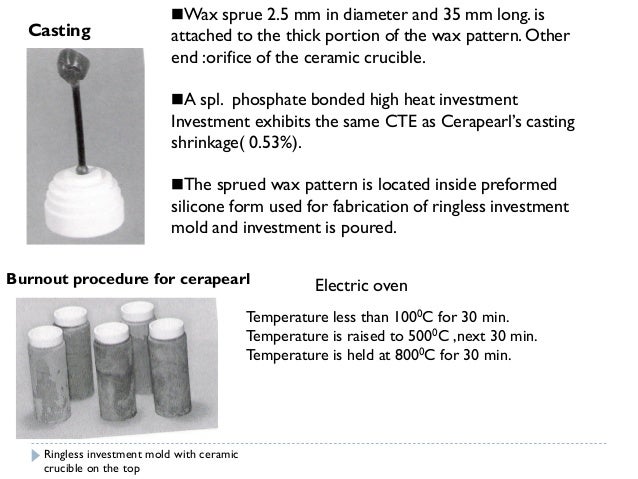

In dentistry casting is a process by which a detailed wax pattern of a dental restoration is converted into alloy or ceramic. Spruing technique direct the flow of molten metal is straight direct from casting crucible to the pattern. Versatility the inherent strength of pressed ceramic porcelain supports a much larger range of treatments and restorations than feldspathic material. Number of sprues single double multiple 17.

Esthetically these materials are preferred alternatives to the traditional materials in order to meet the patients demands for improved esthetics. The casting process allows the dentist and dental laboratory to custom make precision restorations for. It is common to use indirect spruing for multiple single units and fixed partial dentures. In direct using aconnector or runner bar which the wax pattern sprue is attached.

Ips e max press is a legendary lithium disilicate glass ceramic ls 2 for the press technique. Isostatic pressing is similar to uniaxial pressing in the requirements for the powder and in the general steps of the process but there are several important differences. That is the pressure is transmitted to the part equally in all directions or. Dental ceramics are usually composed of nonmetallic inorganic structures primarily containing compounds of oxygen with one or.

Pressable ceramics consider the following when designing the sprue channels of pressed ceramic patterns. This synergy combines the strength fracture toughness and cementability of pure zirconia copings with the marginal integrity versatility and beauty of pressable ceramics. The ingots are available in five translucency levels and in an impulse version. The polychromatic ips e max press multi ingots are particularly attractive showing a lifelike colour transition.

Francis in materials processing 2016. For crowns this is generally a cusp tip. Oxide ceramics and pressable ceramics. Casting ring and liner 18.

Crowns and bridges are sprued directly with a 2 5 to 3 mm wax wire without corners and edges at a 45 to 60 angle to the mold cavity former. First the compaction takes place under hydrostatic conditions. Heat pressed all ceramic materials leucite based ceramic first generation heat pressed ceramics contain leucite kalsi2o6 or k2o al2o3 4sio2 as reinforcer heat pressing temperatures. A connector or reservoir bar is positioned between the pattern and crucible former.