Spark Plasma Sintering Ceramics

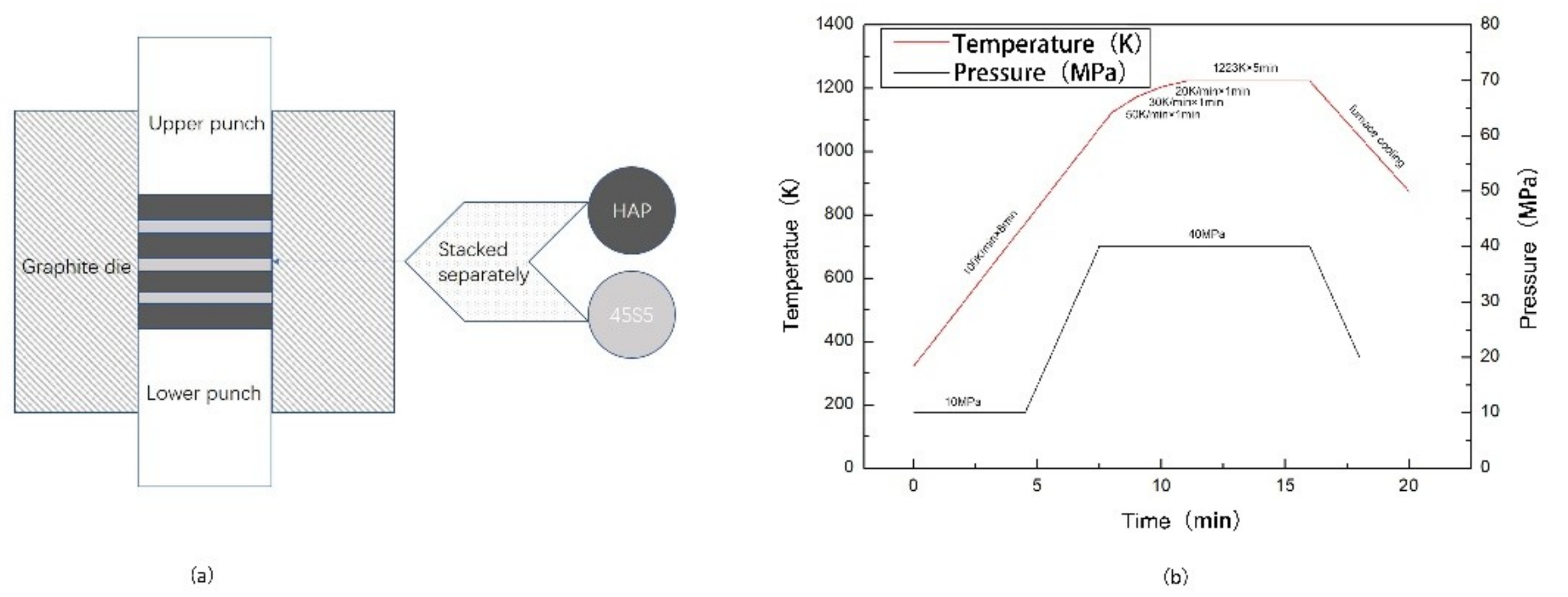

Spark plasma sintering problem statement spark plasma sintering sps also known as pulsed electric current sintering pecs or field assisted sintering technology fast employs a pulsed dc current to heat up an electrically conductive tool and possibly powder compact by joule heating.

Spark plasma sintering ceramics. 10 thanks to the good electrical conductivity of the materials used. 1 4 2 1 4 2 2 2 1 22 2 1 2 r t q r q q t r emissivity of graphite die stefan boltzman constant. That flash spark plasma sintering technique or flash hot pressing could consolidate silicon carbide powder up to full density in just seconds with the help of a specially designed tooling die. It allows very fast heating and cooling rates very short holding times and the possibility to obtain fully dense samples at comparatively low sintering temperatures typically a few hundred degrees lower than in normal hot pressing.

Spark plasma sintering sps has emerged as a highly promising technique for materials sintering and production and can be used in surface coating and finishes as well as bulk material productions. The san diego state team s new work is the next step forward for the technique. Spark plasma sintering sps also known as field assisted sintering technique fast or pulsed electric current sintering pecs or plasma pressure compaction p2c is a sintering technique. The main characteristic of sps is that the pulsed or unpulsed dc or ac current directly passes through the graphite die as well as the powder compact in case of conductive samples.

Spark plasma sintering sps is a comparatively new technique. Ceramics international 2008 simulation of temperature profiles in sps surface temperature. Spark plasma sintering consists of a mechanical loading system such as hp but instead of an external heating a pulsed electric current flows through the punches through the mold and depending on the electrical conductivity also through the powder compact within the die. With the increase of the amount of caf2 the density and transmittance of the samples increase.

Transparent caf2 doped aln ceramics were prepared by spark plasma sintering sps at 1850 c for 15 min. Matlab simulation of temperature profiles in sps.