Sov Powder Metall Met Ceram

Technology of forming processes.

Sov powder metall met ceram. Tic and ni3al are the only phases detected in. For ni 3 al contents from 8 to 25 vol. A simple melt infiltration processing route has been developed for the fabrication of tic ni 3 al ceramic intermetallic composites which involves a combination of infiltration and subsequent liquid phase sintering. Solid state diffusional reactions preceded the main.

The formation of m 6 x type compounds ti 4 cu 2 o or ti 3 cu 3 o at the interface is characteristic of these joints. The al nb phase diagram from massalski et al. Krushinskii conditions of preparation of complex carbide alloys containing scandium carbide sov. 1 illustrate the formation of a single hexagonal diboride phase for sample b3 and a single cubic carbide phase for sample c1.

3 moderate levels of nb segregation are observed in both the boride and carbide. Powder metallurgy and metal ceramics covers topics of the theory manufacturing technology and properties of powder. Powder metallurgy and metal ceramics is a translation of the peer reviewed ukrainian journal poroshkovaya. In the brazing process ti in the braze alloy reduces al 2 c 3 to form a series of reaction products which have a layered morphology.

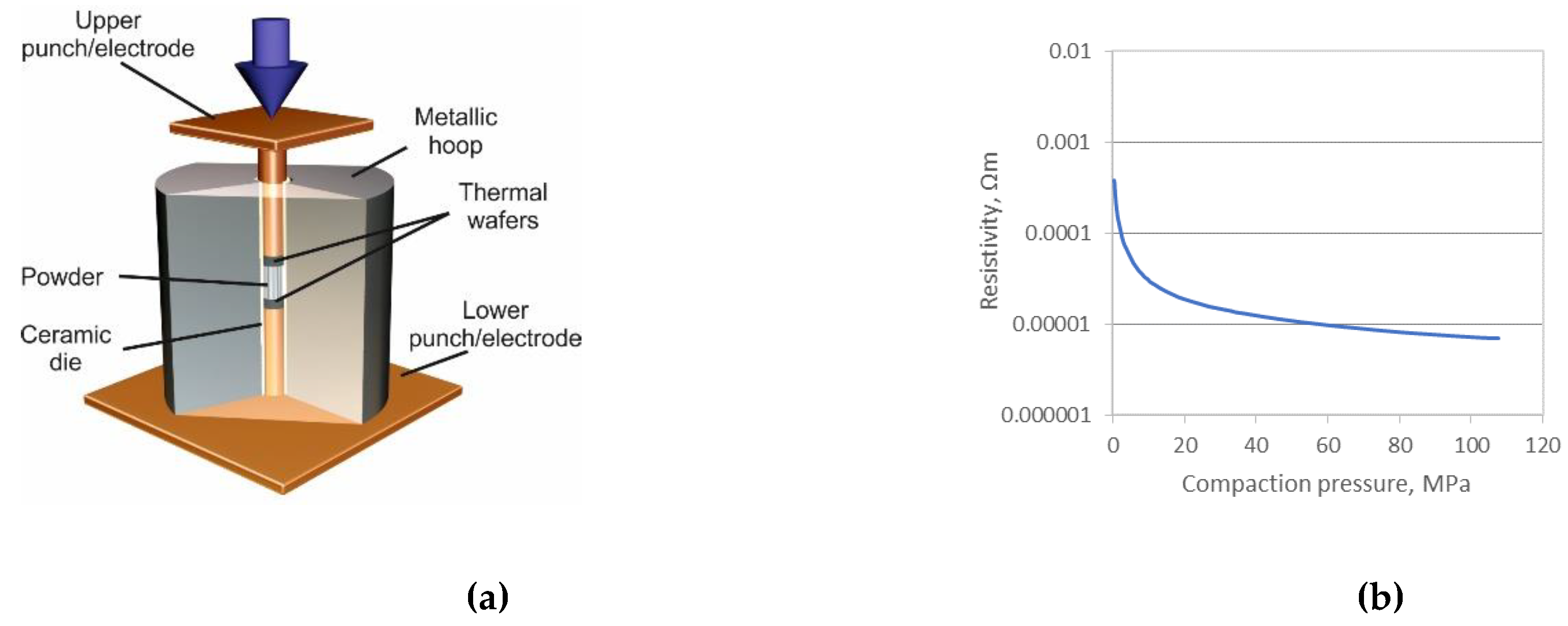

Properties of sintered materials. Powder metallurgy can proceed in two fundamentally different ways for the fabrication of products from powders of refractory borides. The formation of cu al alloys by the thermal explosion mode of the combustion synthesis method was investigated for compositions ranging from 25 to 50 at. A comprehensive review and assessment of the electromagnetic forming process is presented.

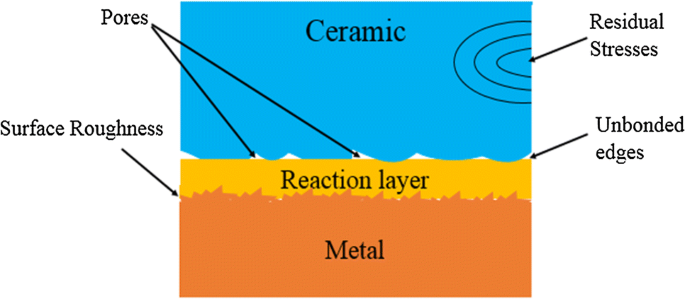

The joints formed by brazing al 2 o 3 to itself or to a ti alloy ti 6al 4v with a ag cu ti braze filler were investigated. Through x ray differential thermal analysis dta and scanning electron microscopy sem analyses the nature of the reaction between powders of the two metals was determined. 1 presents alnb 3 with a wide homogeneity range which extends from 18 6 at al below 1773 k to the stoichiometric composition alnb 3 25 at al at 2213 k we studied the formation of alnb 3 at the composition al 0 20 nb 0 80 at 1699 k and the enthalpy of formation after four measurements was. Even though electromagnetic forming is a technology known for a few decades renewed interest in it for industrial applications is currently taking place.

One way conventional sintering includes molding or. δ f h al 0 20 nb 0 80. The quantitative yield of carbonyl iron powder is 1 5 1 7. The technology of sintering heat treatment and thermo chemical treatment.

For the manufacture of r 100f 1 powder the fine powder fractions from cyclones 2 3 and 4 are used.