Solid State Metal Ceramic Bonding Of Platinum To Alumina

The application of temperature pressure and time in a new way to form bonds between a wide range.

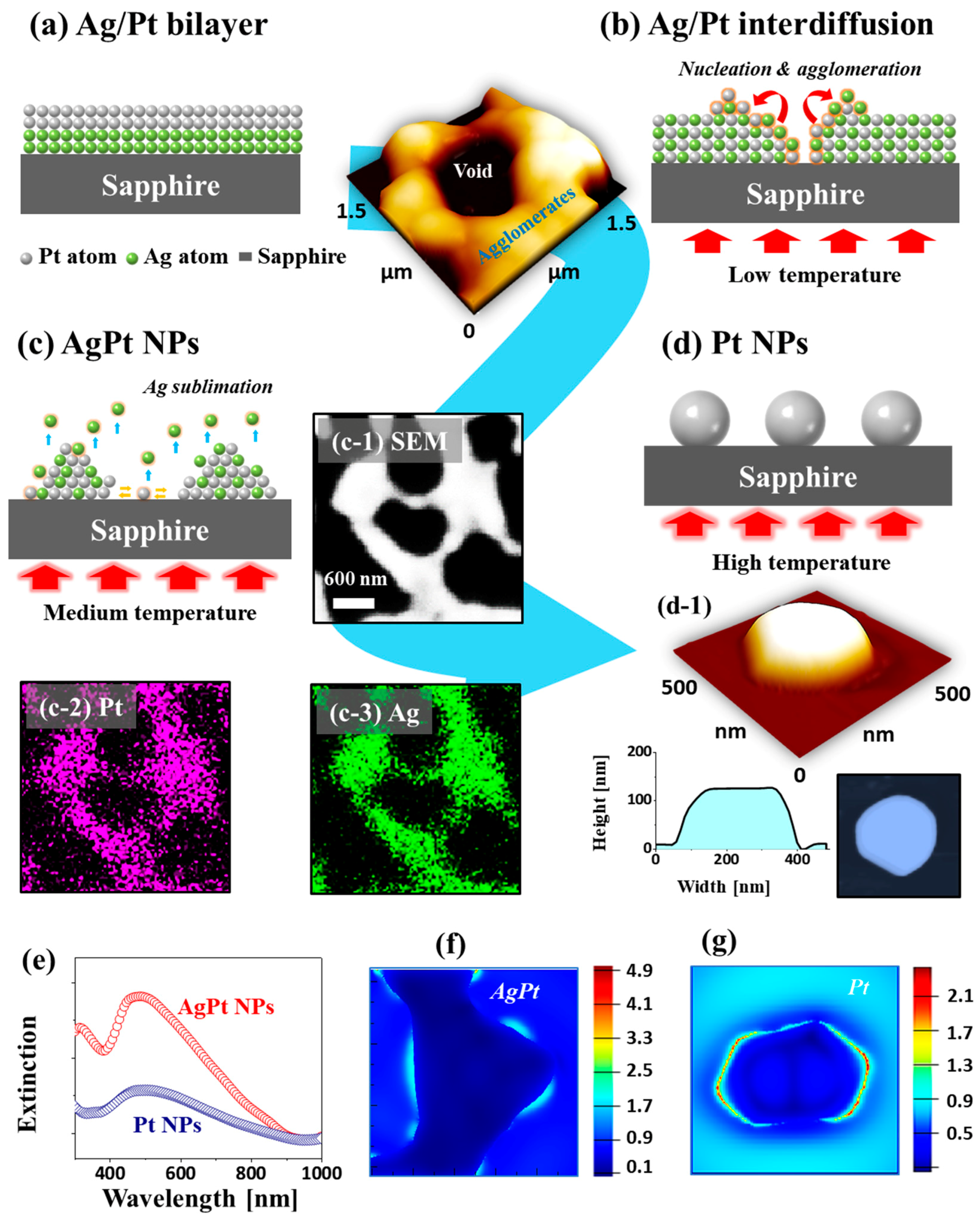

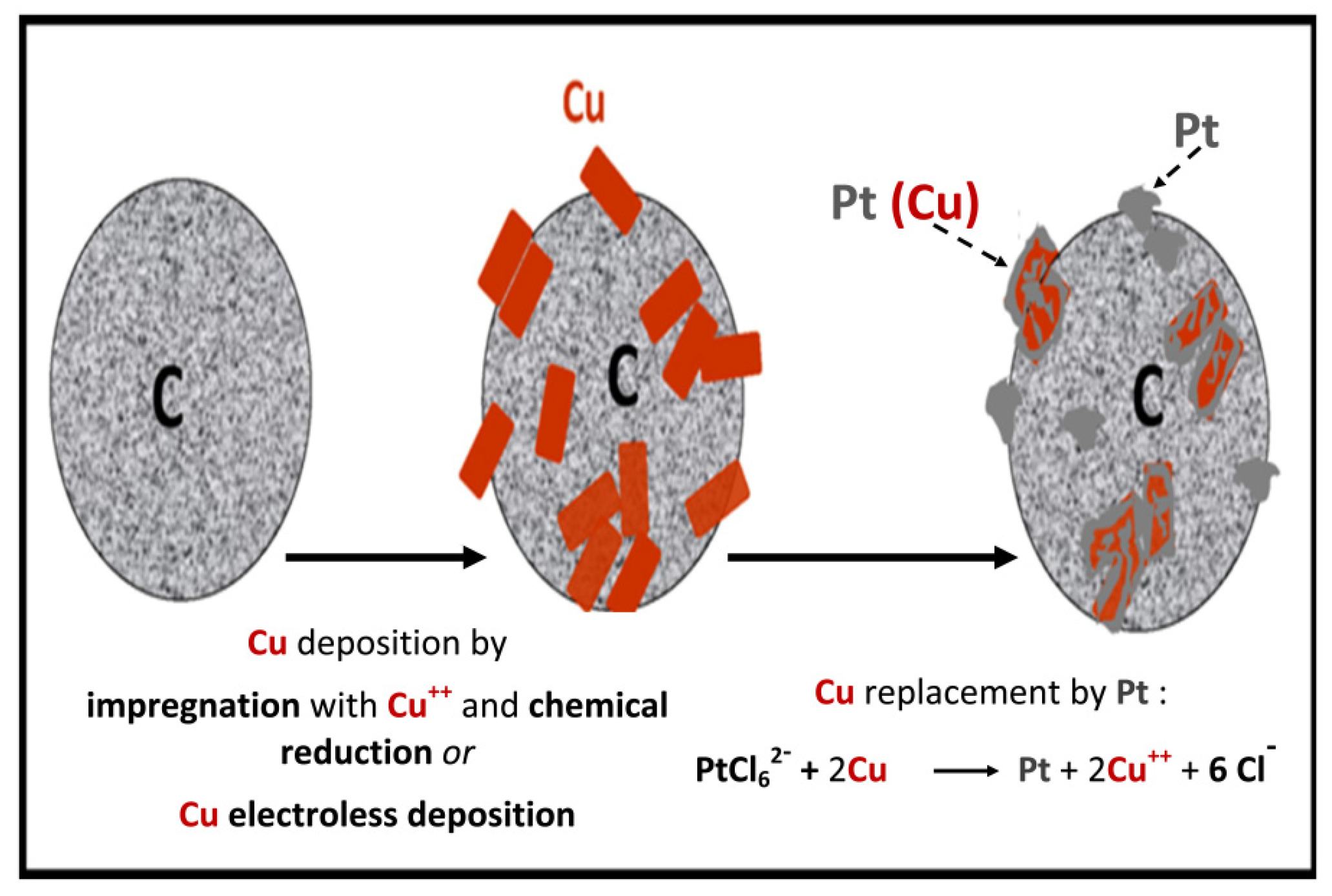

Solid state metal ceramic bonding of platinum to alumina. When soldering atoms diffuse from the solder into the grid of the material and when soldering metals also atoms of the material diffuse into the structure of the solder. Solid state bonding utilizing the diffusion of inserted metal has been also investigated for metal to ceramics bonding. Request pdf brazing oxide ceramics via the ductile interlayers of niobium and noble metals optimized processes for obtaining the braze welded joints of oxide ceramics based on al2o3 and zro2. A solid state bonding technique under hot pressing was used for joining alumina with thin metal sheets of ni cu and fe.

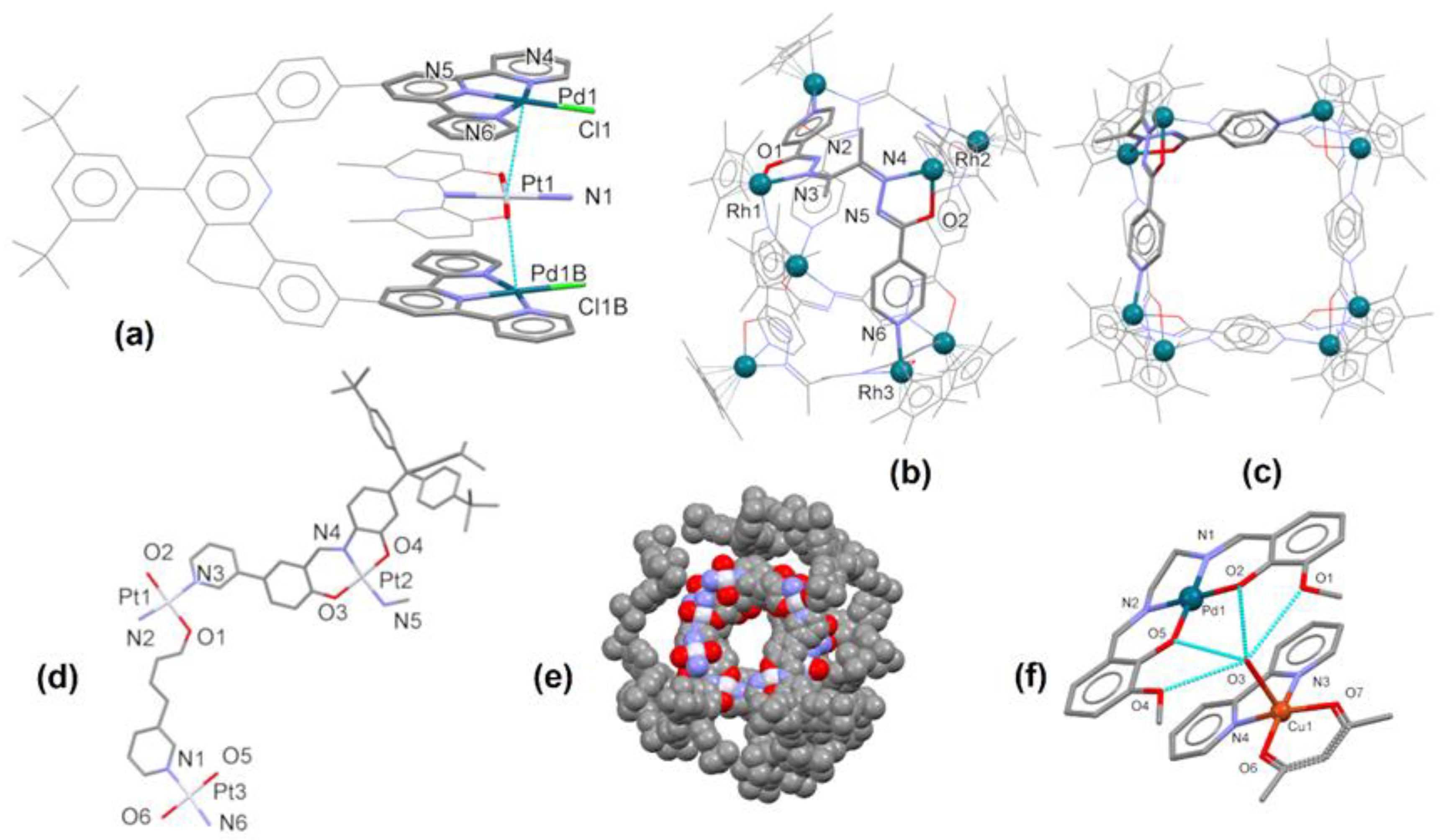

The formation and resulting mechanical strength of solid state metal ceramic reaction bonds of alumina to platinum are investigated in terms of the effects of three main parameters bonding temperature time at temperature and contact pressure. The microstructure and microchemistry of the ceramic metal interface and. The solid state reactions that take place between many ceramics and metals can be utilised to produce strong vacuum tight joints that maintain their strength and durability even at elevated temperatures. The standard joining process at alumina systems for the manufacture of metal ceramic composite components is the soldering of ceramics to metals.

Solid state metal ceramic bonding is a teqhnique which follows the general principles of solid phase metal metal joining techniques i e. Platinum alumina reaction bonds have been tested up to journal de physique. Not available adshelp at cfa harvard edu the ads is operated by the smithsonian astrophysical observatory under nasa cooperative agreement nnx16ac86a. Diffusion into al 2 o 3 results from the bulk diffusion through the grain boundary or.

Also the effect of the subsequent operating temperature on the bond strength is examined. When non noble metals form part of the combination solid state bonding appears to involve a totally different mechanism with metal diffusing into the ceramic and reaction zones forming. The bonding temperature is usually equivalent to the melting point of the inserted metal in order to promote diffusion into ceramics. Here solid state bonding is studied over a broader range where the most influential factors dictating it will be determined after carrying out many press and roll bonding experiments with eight metal metal bonding systems.