Sol Gel Process For Ceramic Preparation

This sol gel process is well adapted for composite nanopowder synthesis and oxide nps 38 and as well as for access to organic inorganic materials 39.

Sol gel process for ceramic preparation. The sol gel method has been also applied to the preparation of double component and multicomponent oxide glass and ceramic fibers which are listed in table 2 the sio 2 based binary glass fibers were obtained from the mixtures of teos and other metal alkoxides dissolved in the dehydrated ethanol in a similar manner to pure sio 2 glass fibers. Cordierite ceramics were prepared by sol gel process using metal salts and a metal alkoxide as the starting materials and their electrical and thermal properties were studied. Homogenous multi component systems can be easily obtained particulary homogenous mixed oxides can be prepared by mixing the molecular precursors solutions 1. Sol gel process technology and chemistry illustrated overleaf preparation of metal oxides using.

This work presents the preparation of alumina aerogel via sol gel route utilizing ambient pressure drying. The preparation of short alumina fibres has been. Effect of dopants on synthesis of bati4o9 and ba2ti9o20 ceramics prepared by reaction sintering process journal of the european ceramic society 10 1016 j jeurceramsoc 2006 11. By means of a sol gel method and a combustion method.

These pigments need to be stable homogeneity colour intensity crystallinity at high temperatures in a glaze. Malayaite ceramic pigments casnsio5 in this research study have been prepared in two ways. Sol gel process for the preparation of ba 2 ti 9 o 20 and bati 5 o 11. The sol gel process is a wet chemical technique used for the fabrication of both glassy and ceramic materials.

Ceramic pigments are extensively used in the decoration of ceramic wares. A novel and efficient solvent exchange process has been utilized as an alternative to conventional solvent exchange processes by directly boiling the hydro gel in solvent. Sol gel process provides a new approach to the preparation of new materials. Typical precursors are metal alkoxides and metal chlorides which undergo.

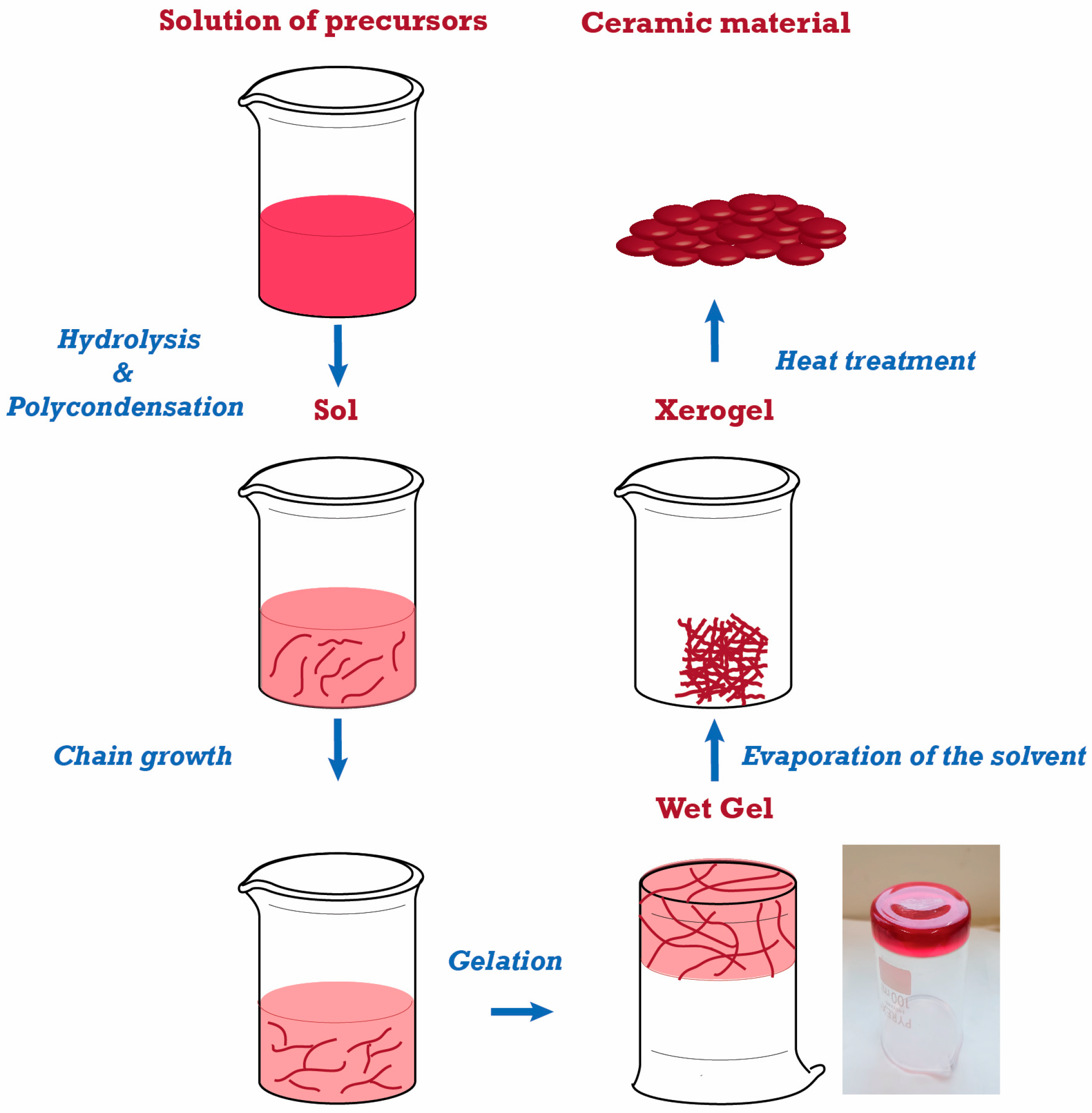

Usually the melt spinning method is adopted for the synthesis of ceramic fibres with low melting point. Sol gel is a method for preparing specialty metal oxide glasses and ceramics by hydrolyzing a chemical precursor or mixture of precursors that pass sequentially through a solution state and a gel state before being dehydrated to a glass or ceramic. In this process the sol or solution evolves gradually towards the formation of a gel like network containing both a liquid phase and a solid phase. Thus this method is not suitable for the preparation of the alumina fibres.

Any other salts did not give a homogeneous solution and deposited after gelation. The sol gel process allows the synthesis of ceramic materials of high purity and homogeneity by means of preparation techniques different from the traditional process of fusion of oxides. Department of chemical engineering iowa state university ames iowa 50011. The starting substances in the sol gel method was teos ca no3.

Best starting materials were aluminium nitrate magnesium acetate and tetraethoxysilane.