Sol Gel Process For Ceramic Coatings

The technology also produces high gloss coatings that have the ability to withstand higher temperatures compared to conventional coatings giving cookware a better look and enhanced functionality.

Sol gel process for ceramic coatings. Formulators usually try to avoid chemical reactions within their formulations due to the fact that it could affect the quality and functional properties of the eventual coating. Sol gel coating systems are a hybrid of organic and inorganic chemistry otherwise known as ceramic coatings that is free of pfoa and ptfe. Sol gel coatings feature a wider range of colors like blue red green and even white and are able to preserve the color at higher temperatures. Introducing sol gel ceramic coatings the hybrid ceramic coating with excellent heat resistance and non stick properties.

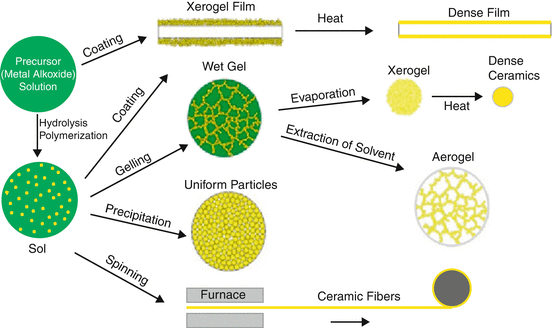

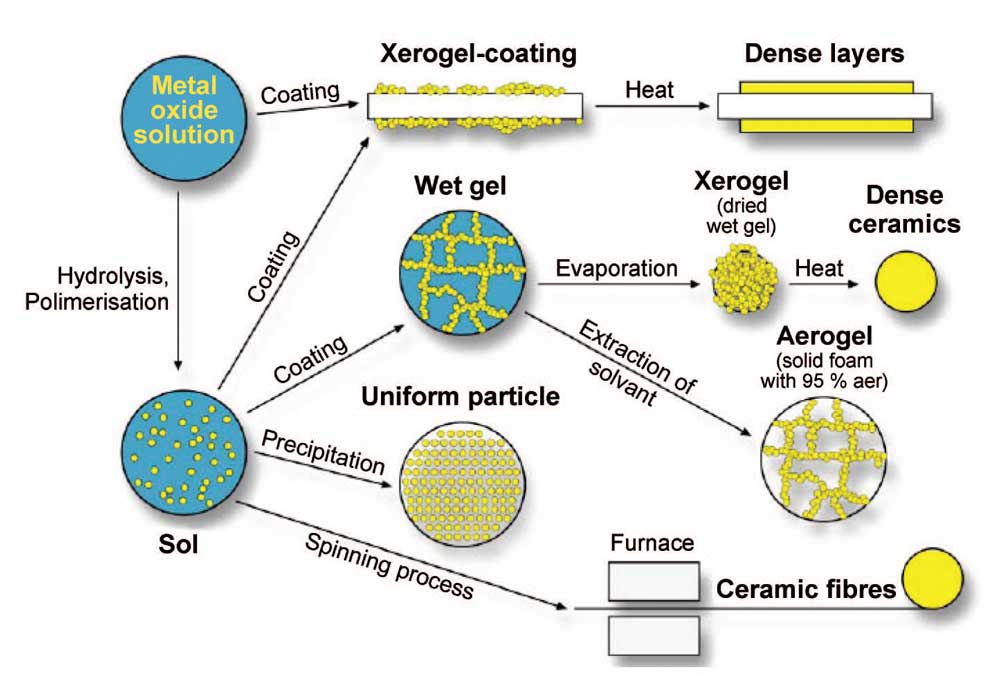

The sol gel process is a wet chemical technique used for the fabrication of both glassy and ceramic materials. Electrophoretic sol gel coating of sio 2 was performed on dc etched and electropolished aluminum and then anodizing was carried out to examine the dielectric properties of anodic oxide films formed by the two successive steps. Traditionally non reactive systems are preferred by nonstick coating producers. Sol gel research grew to be so important that in the 1990s more than 35 000 papers were published worldwide on the process.