Sol Gel Coating Of Powders For Processing Electronic Ceramics

A modification of spray roasting known as rapid thermal decomposition of.

Sol gel coating of powders for processing electronic ceramics. The following conclusions may be drawn. A long shelf life 164. The temperature and transit time are adjusted so as to accomplish rapid evaporation and oxidation. Sol gel science and technology.

The sol gel process is a versatile solution process for making advanced materials including ceramics and organic inorganic hybrids. Sol gel derived abrasion resistant coatings with. The unique chemical formulation of whitford worldwide s fusion sol gel coating which surface technology is an approved applicator of results in a coating which combines the best characteristics of sol gel s ceramic and polymer molecules. This report is directed to producers and users of materials and applications related to sol gel processing.

Glass ceramics and organic inorganic materials can be processed by sol gel techniques. Thermal insulation 165. The reaction is called hydrolysis because a hydroxyl ion becomes attached to the silicon. The stöber process is a well studied example of polymerization of an alkoxide specifically teos the chemical formula for teos is given by si oc 2 h 5 4 or si or 4 where the alkyl group r c 2 h 5.

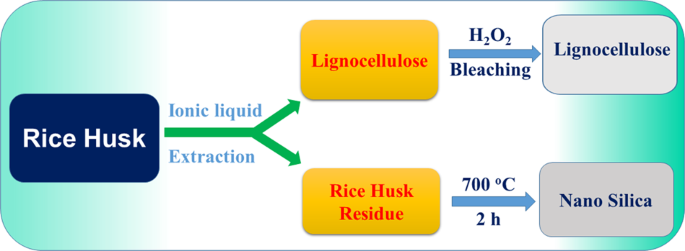

Companies involved in the development manufacturing and supplying of advanced materials. Sol gel processing process has been used to produce a wide range of compositions mostly oxides in various forms including powders fibers coatings and thin films monoliths and composites and. The way of making materials in any form including fibers films particles and monolithic solids starting with liquids and molecular precursors. Sol gel has produced a wide range of compositions mostly oxides in various forms including powders fibers coatings thin films monoliths composites and porous membranes.

Developers and producers of ceramic powders for electronic and structural applications. Advanced ceramics advanced ceramics spray roasting. Aerogel windows 165. The result is a high purity powder with fine particle size.

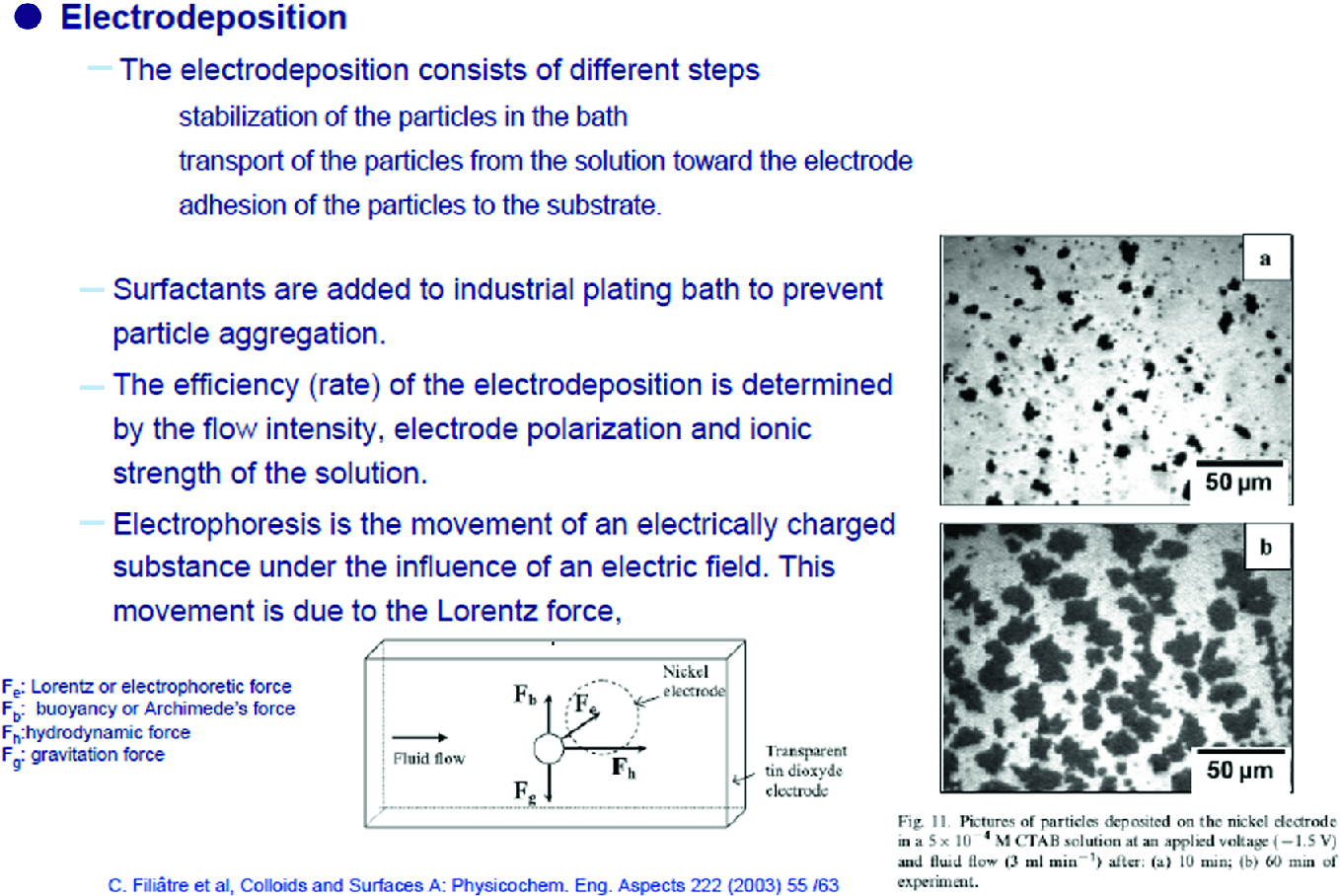

Spray roasting involves spray atomization of solutions of water soluble salts into a heated chamber. A new technique sol gel coating of powders was utilized to process electronic ceramics such as sb doped sno2 and positive temperature coefficient of resistance ptcr batio3 thermistors. Electrophoretic sol gel coating can form sio 2 films uniformly on the surface of plain and dc etched specimens. Toughness impermeability and thermal stability of a ceramic combined with the chemical inertness and non stick properties of a polymeric material.

Electrophoretic sol gel coating of sio 2 was performed on dc etched and electropolished aluminum and then anodizing was carried out to examine the dielectric properties of anodic oxide films formed by the two successive steps.