Sol Gel Ceramic Coating

Electrophoretic sol gel coating can form sio 2 films uniformly on the surface of plain and dc etched specimens.

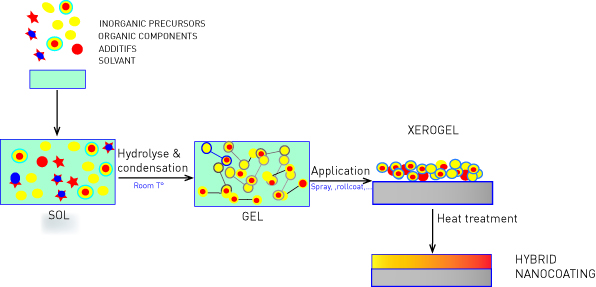

Sol gel ceramic coating. The associated technology is a mix of totally different chemistry types namely organic and inorganic. The suspended particles undergo hydrolysis through the addition of water and subsequent condensation polymerisation where molecules join together and form a gel where the gel element of sol gel comes from. Made without pfoa and ptfe fusion is a coating system based on sol gel technology. The fusion family of coatings fusion fusion ti fusion hr fusionx work to extreme temperatures cure at lower temperatures using less energy and are waterborne.

Sol gel is not a ceramic. Traditionally non reactive systems are preferred by nonstick coating producers. Beside silk screen printing continuous 21 and discontinuous 22 ink jet printing of sol gel ceramic and organic inorganic hybrid coating materials have been applied to ceramic and glass surfaces to obtain decorative coatings and micro optical elements micro lenses and micro lens arrays. The sol element of sol gel is a solution in which particles are suspended.

What is sol gel ceramic coating. Sol gel nanocomposite coatings sol gel nanocomposites are hybrid materials with an inorganic matrix and organic chains that define the properties e g. The combination of ceramic glass like structures with different organic molecules leads to materials with very special properties. Electrophoretic sol gel coating of sio 2 was performed on dc etched and electropolished aluminum and then anodizing was carried out to examine the dielectric properties of anodic oxide films formed by the two successive steps.

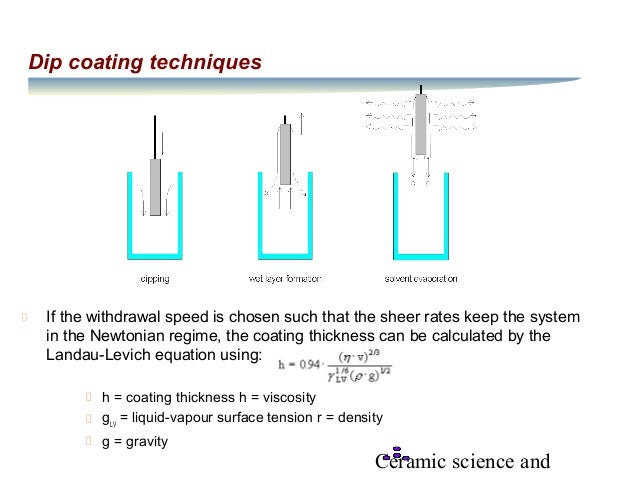

Sol gel consulting services solgelway offers a unique and patented dip coater dedicated to the research and development of sol gel solutions. Sol gel research grew to be so important that in the 1990s more than 35 000 papers were published worldwide on the process. The following conclusions may be drawn. The sol gel process is a wet chemical technique used for the fabrication of both glassy and ceramic materials.

Is sol gel considered a ceramic. Subsequently the gel is applied as a coating to the substrate and is dried to create a hard glossy film. Although sol gel coatings carry many of the same characteristics as ceramics.